Second House Products

-

0+

Years in the market and we continue to thrive

-

0-0%

Of production output is dedicated for export markets

-

0%

Striving continuously to delight our customers in products and services offered

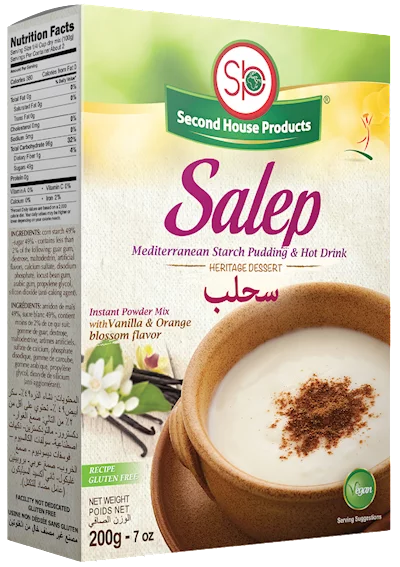

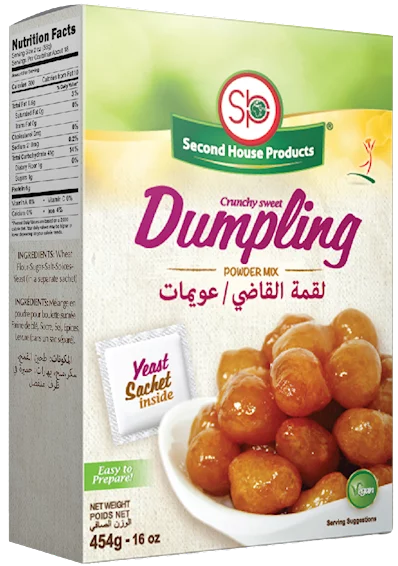

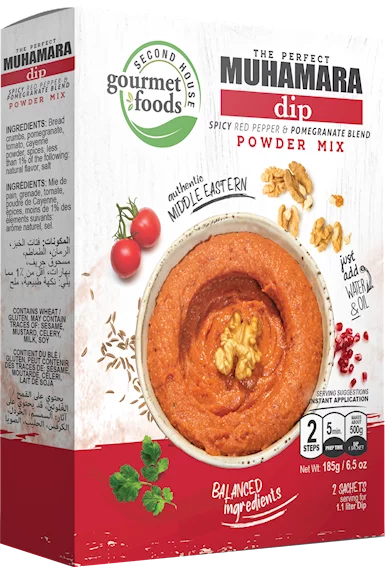

Offering Middle Eastern goodness

Authentic flavors and marinations

Shop our products

Find your next favorite cooking adventure

Popular Recipes

Our captivating world

Let's craft delightful recipes together

A delectable journey through tantalizing recipes, savory secrets, and delightful culinary adventures!

-01-medres.webp)

-01-medres.webp)